Solar PV microgeneration has become a popular option for homeowners in Ireland in recent times, certainly helped by the introduction of an SEAI grant in July of 2018. Given my own personal interest in solar and IoT I checked if I was eligible for the grant and happily I was. A back of an envelope calculation showed a 6 year payback in terms of electrical energy saved based on a 75% reduction in imported energy from the grid which is reasonable. It also improves the BER rating for my house which makes it more salable so should pay for itself one way or another. And yeah its green too – saving maybe 4 tonnes of carbon per year.

I engaged next gen power to commission a system for me and this was finally installed last week. I went for the larger install of 18 panels (325W each, 6kWp total), a 5.8kW inverter and a 5.8kW battery. When I saw the effort they had to put in I was glad I didn’t consider going the self install route (which wouldn’t be grant eligible anyway).

There were some minor setbacks along the way, but nothing insurmountable. The first issue was that while I do have a large south-facing garage roof which I presumed would be ideal for mounting panels, it turns out that the dormer windows would make this awkward so the installers recommended a ground mount system instead. This was fine with me since I had the space for it. There is an area behind (west) the garage which is out of sight and a pain to keep anyway so losing a few metres of grass suited me just fine.

The panels are out of sight as you can see here. Only the cattle in the field behind us can see them and they probably won’t complain.

Most of the gear is in the garage which suits me fine too. And avoids complaints from herself about filling the utility room with equipment. The inverter and battery are rated for outdoor installation but I do prefer them indoors. The LiFePO4 battery tech is less prone to exploding (!) than regular Li-ion batteries but still better to not have it in the house as far as I am concerned.

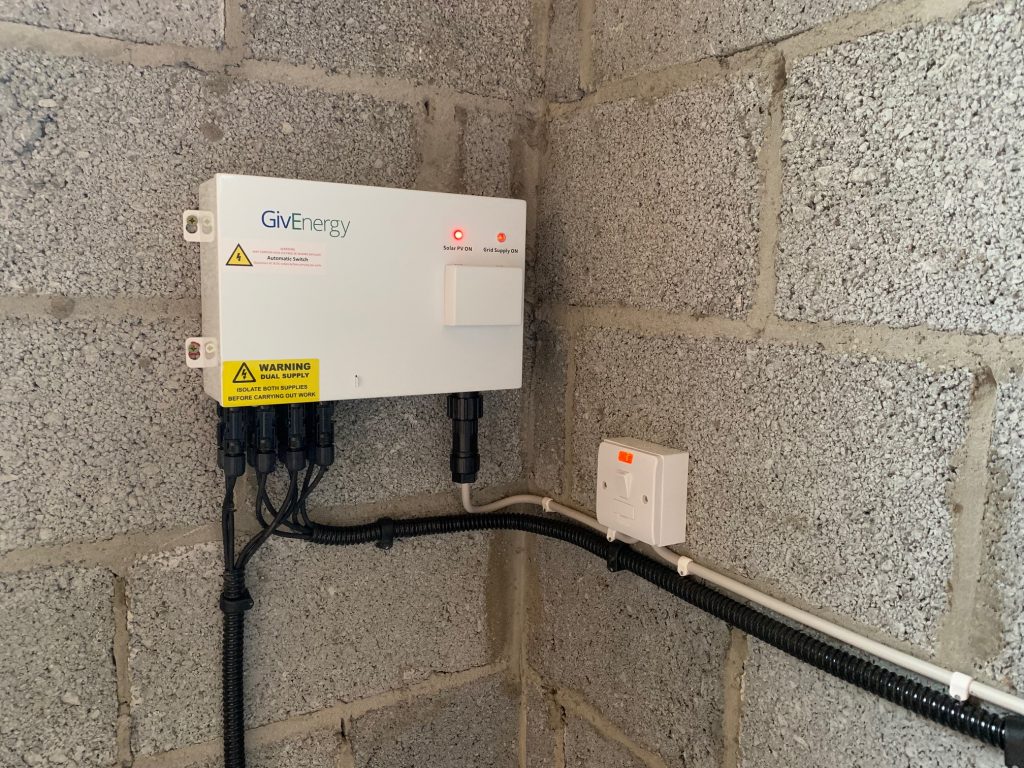

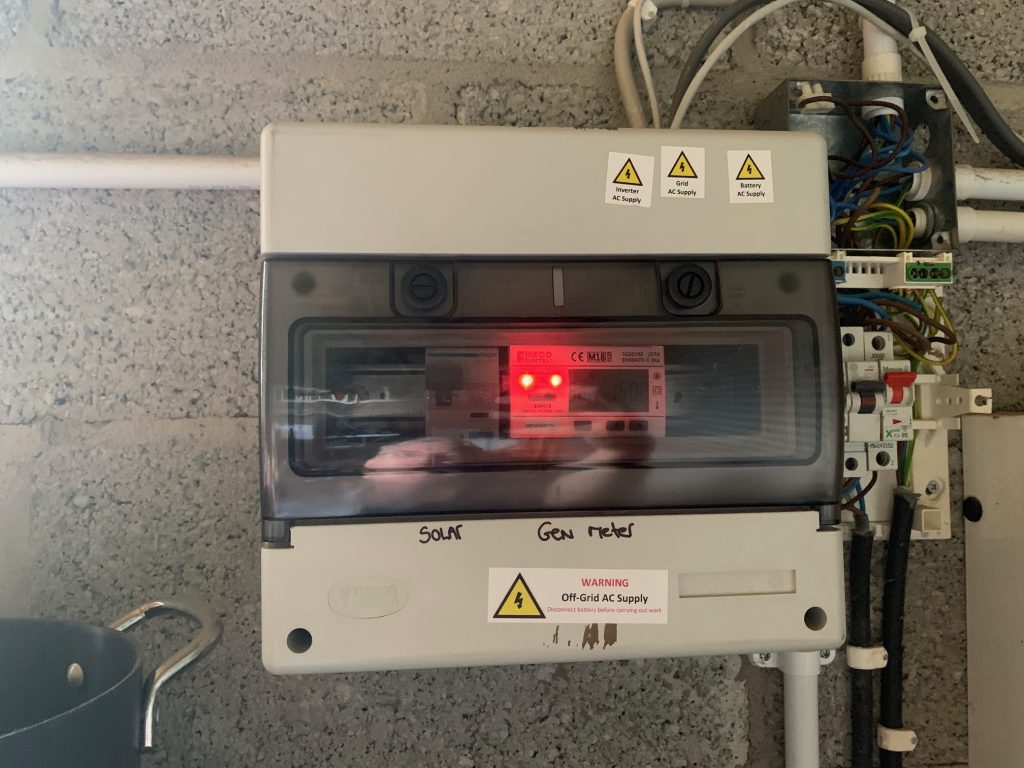

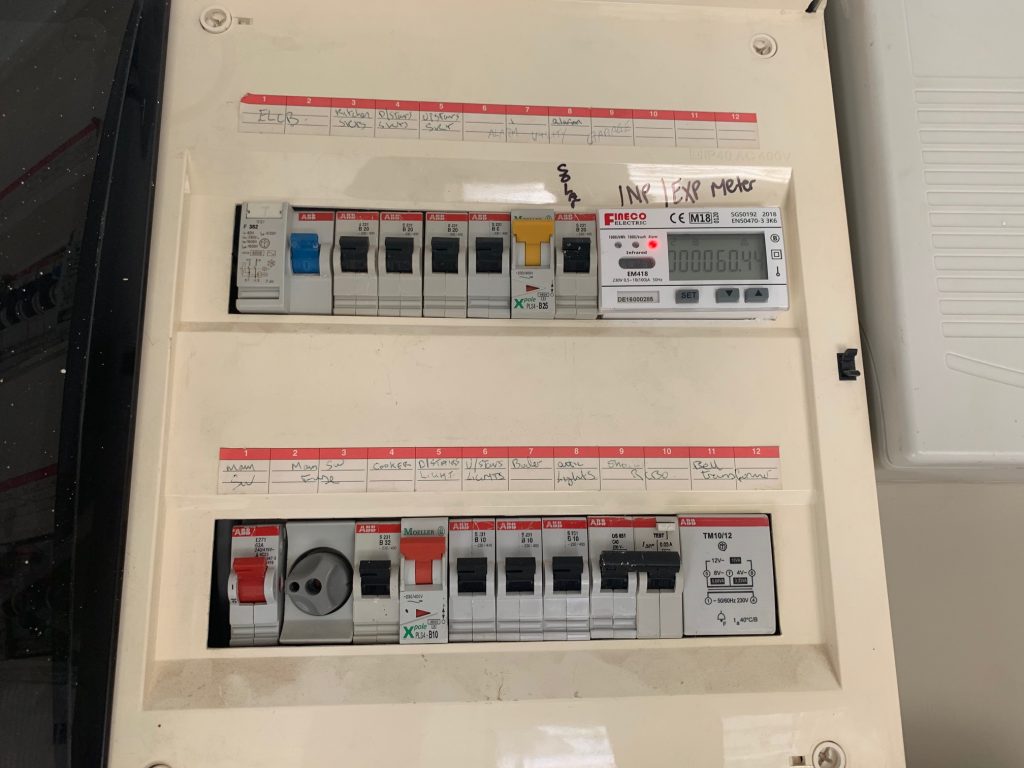

There is a small consumer unit at the house (east) end of the garage where a new panel was installed with another meter. The wiring for the garage is a little messy (always was) so I plan to put in a new switch panel here at some stage with individual circuits for lighting and sockets (an item for the TODO list). The plan is to have lights controlled by PIR and to have some sockets driven from the essential loads circuit. The electric gates and a few other items are already distributed from here.

The wiring between the garage and the house needed a bit of work. The existing feed from the main consumer board to the garage was a 25A circuit using 2.5mm^2 cabling which wasn’t heavy enough to allow the 5.8kW inverter to drive the house. So we had to run a new cable. I had buried a 1.5″ hydrodair pipe before the tarmac went down so we were able to pull a shielded cable through this to feed the house. I prefer this anyway since now I can isolate the garage individually without losing the PV supply. I ran 2 x CAT5 cables while I was pulling through the power cable. One is for the PV metering, the other for internet. I just need to put some trunking around these cables at some stage to tidy up the entry point into the garage.

Inside the house, there are some additions to the utility room. The import/export meter has been added to main consumer unit which luckily fit into an empty slot. The garage MCB is now marked “solar”, which I may put on a separate one in time.

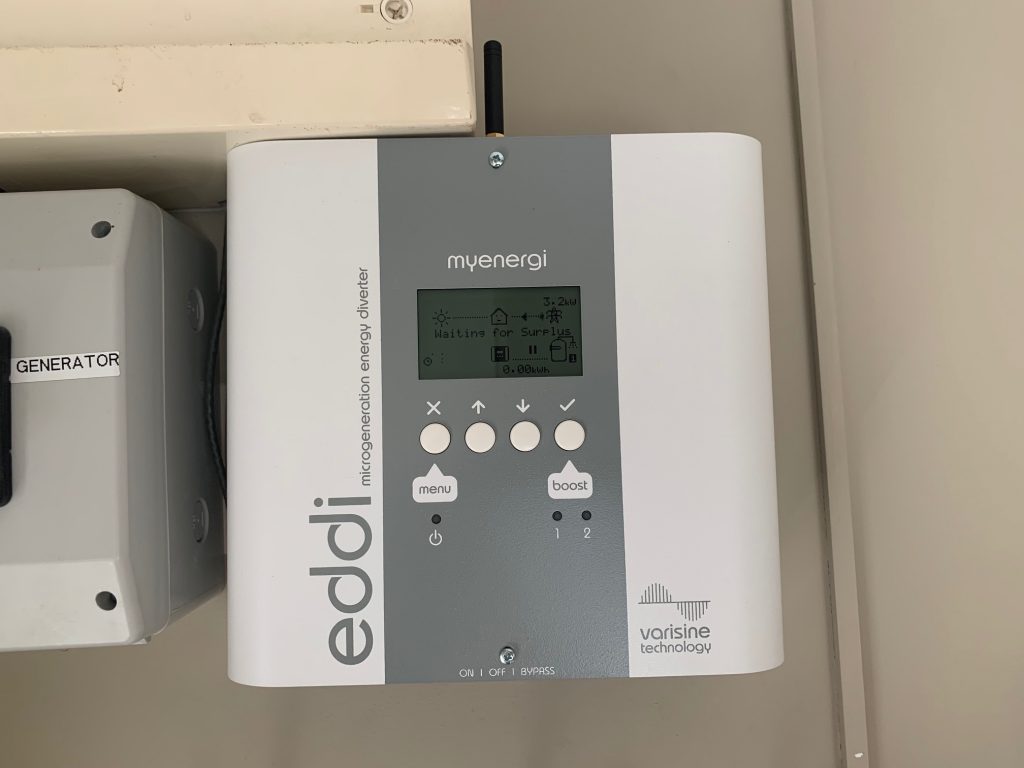

Finally there is “eddi” which is an energy diverter. This is connected to the immersion heater on the hot water tank to use up any excess power. More on this later.

Taking a few pics of the underside of the inverter shows some interesting ports. The two channels from the panels (9 panels per channel, 18 in total) have 4 cables coming into the inverter and there are two heavy cables to link to the battery (DC coupling).

The comms ports are more interesting. There is a USB port which has the WiFi dongle installed. This is configured to associate with the access point in the garage to give me telemetry from the inverter.

Temporarily removing the dongle and the cover over the comms ports shows that there are two RS485 ports. One for the import/export meter installed in the main house consumer board and one it seems for the battery which also has an RS485 port. There is an ethernet port too which I hope is a MODBUS/TCP port so I can query the inverter myself.

Having a peek under the mains output cover reveals the essential supply terminals. In time I plan to use these to power my server, the freezer, the boiler, the septic tank pump (it’s not pretty if that loses power) and maybe a few lighting circuits and sockets for phone chargers and so on. We do have fairly frequent power cuts out here and while the inverter can’t work in island mode (or can it?) at least the essential supply can be used for emergency power backup.

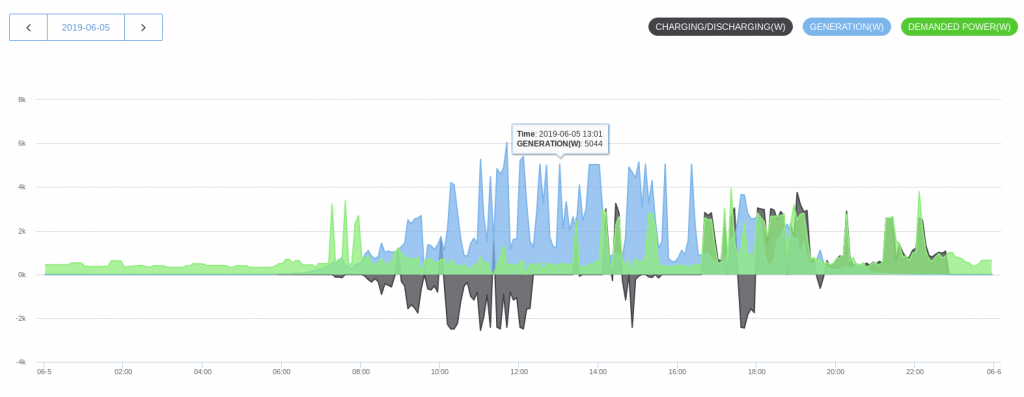

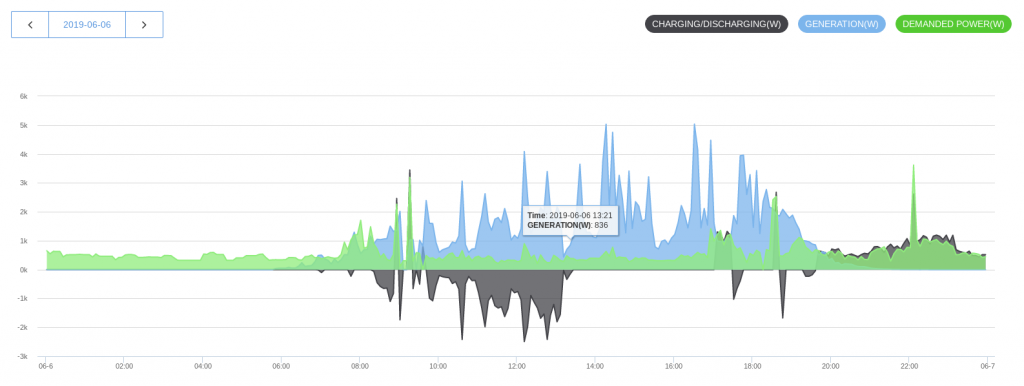

The givenergy portal is very good, but the updates are only every 5 minutes. Presumably the reports are an average over the 5 minutes and not a discrete sample but I won’t know for sure until I add my own telemetry. This snapshot shows a reasonably sunny day and the inherent problem of mismatched production and consumption. The battery is full at lunchtime but is empty again by 10pm. We will have to see in time if another battery is justified.

I have some initial observations after one week. It is definitely going to take some getting use to matching the production and supply. Most days even in the cloudy weather we had in the last week, there is more than enough energy supplied by the PV array (about 20kWhr) to cover the daily demand (about 18kWhr). But I am still exporting 2 or 3 kWhr per day. A bigger battery would help, but the payback may be too long if it only saves 2 kWhr per day.

Eddi helps BUT I am concerned the reaction time may be too slow. If sunshine is erratic, as it has been over the last few days, the switch from export to import occurs quickly and often. I wonder how often the inverter and the eddi read the import/export meter and react. Averaging out import and export doesn’t work – we don’t have net metering so exporting has to be minimised.

(UPDATE: The CT for the eddi was initially installed backwards which meant eddi was heating water while importing instead of when exporting. This explains the periodic bursts of battery power usage during the day. This is fixed now.)

Educating the family on how to optimise PV energy is challenging. When I suggested we run appliances during the day, the tumble dryer, washing machine, vacuum cleaner and dishwasher all went on at the same time resulting in an 8kW demand which is more than the inverter can supply so we imported anyway. I had to explain to add load during the day, but not all at the same time.

The PV array is (occasionally anyway) supplying the full 6kW but the battery can only charge at a rate of 2.4kW. This excess can be used to heat water using eddi, but once the water is hot, it gets exported regardless. To maximise the eddi excess diversion, I’ve turned off the gas boiler. But this runs the risk of not having enough hot water on a cloudy day. My teenagers seem to want to stay in the shower until the hot water tank is empty so managing expectations of hot water availability is a challenge.

Automation will help a lot here. Load scheduling by a smart gateway that knows the battery SoC, the scheduled demand, maybe even the weather forecast and coupled with an AI to learn the family demands will be an interesting area to explore.

And this is all happening mid summer. Really I will have to see what a full year looks like before I can accurately predict my payback. But given energy prices are only going up not down the payback should get shorter the longer it is is use so long as I can manage the load scheduling aspect.